atOXmill

2023-11-14T10:11:09+00:00

ATOX coal mill

WebATOX mill is the sturdy bevelhelical or more compact bevelplanetary type gear from MAAG Gear The gears are designed for high dynamic loads with a generous WebFeb 26, 2013 This film demonstrates all aspects of the ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for: ATOX® raw mill YouTube

ATOX® animation for raw grinding YouTube

WebFeb 26, 2013 This is the ATOX movie for raw mill grinding in an animated versionWhether grinding raw coal, clinker, cement and/or slag, we have a vertical roller mill (VWebATOXmill availability The new split seal can be replaced inside the mill, without removing the grinding rollers New ATOX 275 mills and bigger are today as standard equipped ATOX mill split oil seal

ATOX® Coal Mill G7 Equipment

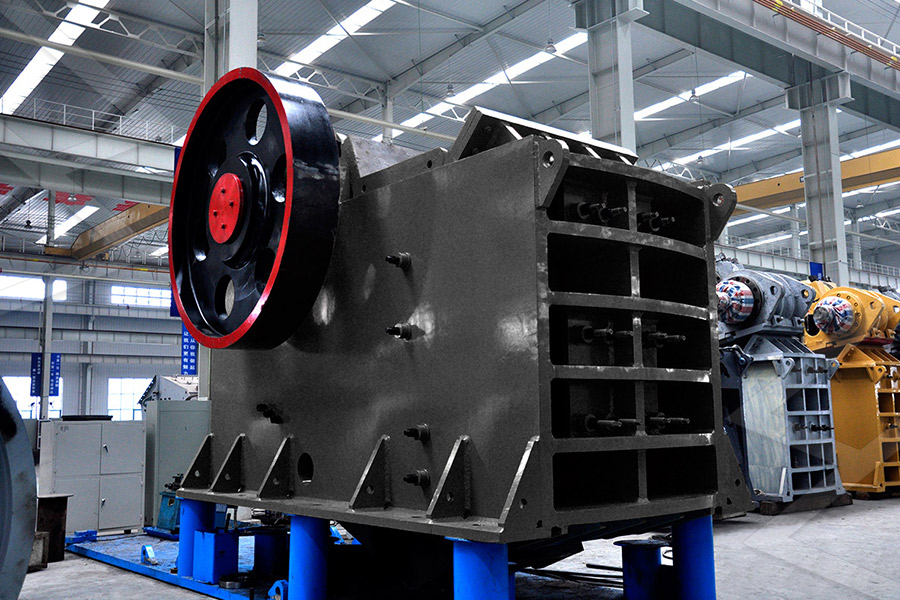

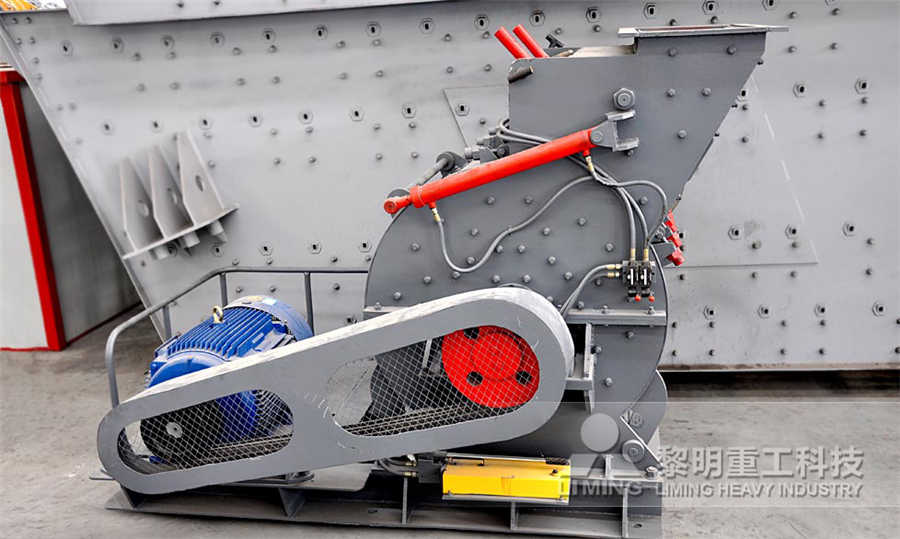

WebRollers help handle virtually any type of coal The ATOX® Coal Mill’s large rollers can handle up to 200mm feed lumps, reducing the need for a separate crusher Large rollers Web44K views, 187 likes, 5 loves, 11 comments, 98 shares, Facebook Watch Videos from World Cement Engineers: How to Work FLsmidth OK Mill # #flsmi #okmill How to Work FLsmidth OK Mill # #flsmi #okmill

ATOX coal mill flsmidth

WebATOX mill is the sturdy bevelhelical or more compact bevelplanetary type gear from MAAG Gear The gears are designed for high dynamic loads with a generous WebAtoxmill; OK™ Pro+ Ceramic Wear Segments; HiChrome Wear Segments; SAG Mill; Press filters; Vertical shaft impact crusher (VSI) FJ JAWS; CONE CRUSHERS; KREBS® Atoxmill G7 Equipment

Rotary sluice for lumpy materials

Webcomponent of the ATOX® mill, FRMTM mill and OK™ mill for many years A range of rotary sluice sizes and capacities are available to match different needs Many applications The rotary sluice can be used in many applications where lumpy materials are fed into process machinery It is most commonly used for vertical rollerWebATOXmill availability The new split seal can be replaced inside the mill, without removing the grinding rollers New ATOX 275 mills and bigger are today as standard equipped with the split seal arrangement For previously supplied ATOX mills the split seal design has also been introduced Conversion kits are now available forATOX mill split oil seal

How ATOX® Split Seal works YouTube

WebFeb 26, 2013 has designed a split inner oil seal for grinding rollers that significantly reduces seal replacement downtime and helps ensure higher ATOX® mill avaWebRollers help handle virtually any type of coal The ATOX® Coal Mill’s large rollers can handle up to 200mm feed lumps, reducing the need for a separate crusher Large rollers also help ensure a thick grinding bed for maximum uptime The roller segments are reversible which ensures the highly durable materials are fully utilisedATOX® Coal Mill G7 Equipment

Atox Raw Mill [PDF Document]

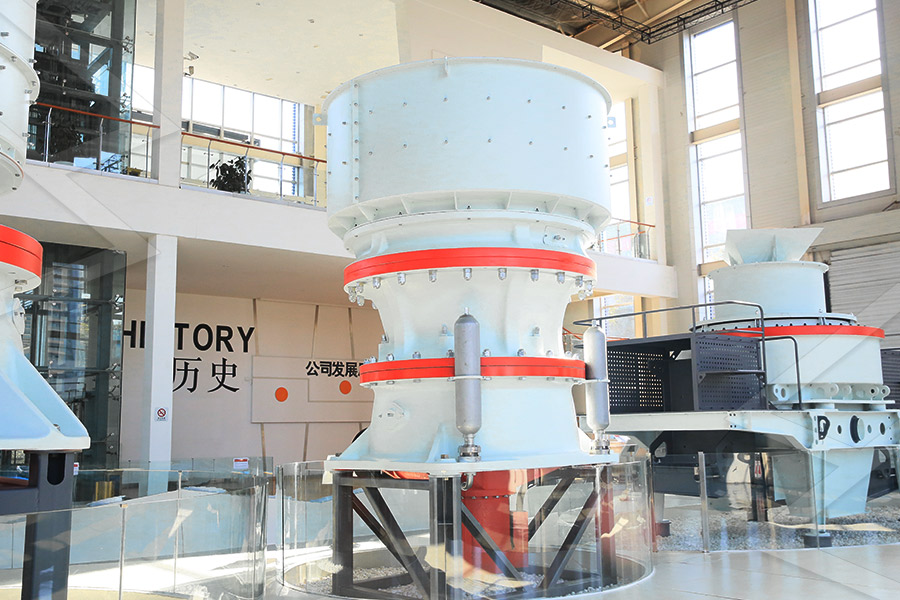

WebNov 2, 2014 The ATOX mill is easily adapted to this situation, as it comes with an oversize nozzle ring and an oversize separator Basic design concept The grinding table of the ATOX raw mill has a flat, horizontal grinding track encircled by an adjustable dam ring and an adjustable nozzle ring equipped with an air guide cone The dam ring is made up of WebFeb 5, 2013 This video is about Atox Mills Hydraulic Unit for grinding rollers Process carried out through various control valves mounted on a hydraulic block called BlAtox Mill Hydraulic unit animation YouTube

How to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill

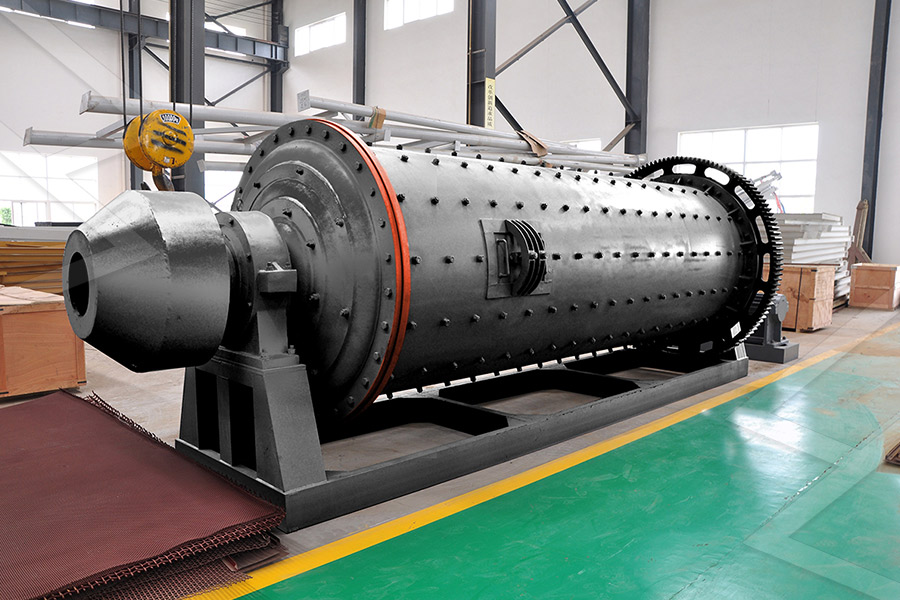

WebMay 10, 2022 44K views, 184 likes, 5 loves, 11 comments, 98 shares, Facebook Watch Videos from World Cement Engineers: How to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill #engineeringWebAtoxmill; OK™ Pro+ Ceramic Wear Segments; HiChrome Wear Segments; SAG Mill; Press filters; Vertical shaft impact crusher (VSI) FJ JAWS; CONE CRUSHERS; KREBS® slurryMAX ™ XD; KREBS® millMAX™ slurry pumps; KREBS® UMD™ Ultimate Mill Discharge Slurry Pump; vMAX™ vertical slurry pumps; KREBS® Technequip® TG Knife Atoxmill G7 Equipment

How to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill

Web44K views, 187 likes, 5 loves, 11 comments, 98 shares, Facebook Watch Videos from World Cement Engineers: How to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill #engineeringWebThe ATOX mill is easily adapted to this situation, as it comes with an oversize nozzle ring and an oversize separator Basic design concept The grinding table of the ATOX raw mill has a flat, horizontal grinding track Atox Raw Mill PDF Mill (Grinding) Bearing

Atox Mill, OK mill, Spare Part, Supplier Verical Roller

WebAtox Mill, OK mill, Spare Part, Supplier Verical Roller Mill Industrial Spare Part Solution +86 e ATOX mill will particles up to the separator that lets the grind and dry coal containing more than 20 final product proceed to the mill outlet per cent moisture in one operation while returning the coarse fraction to the table for further grinding Working principles The ATOX Coal Mill PDF Mill (Grinding) Bearing (Mechanical)

flsmidth atox vertical mill Mining Quarry Plant

WebMay 23, 2013 atox mill – Scribd commenced the There is a number of arrangements for raw material grinding systems involving vertical roller mills 20 ATOX Raw Mill 1 2 3 Mill WebHardfacing a coal mill at a large cement works in Wales, January 2021 #vrm #coalmill #atox #atoxmill #hardfacing #cladding #rebuild #repair #hardfacingBradley White on LinkedIn: #vrm #coalmill #atox #atoxmill

Rotary sluice for lumpy materials

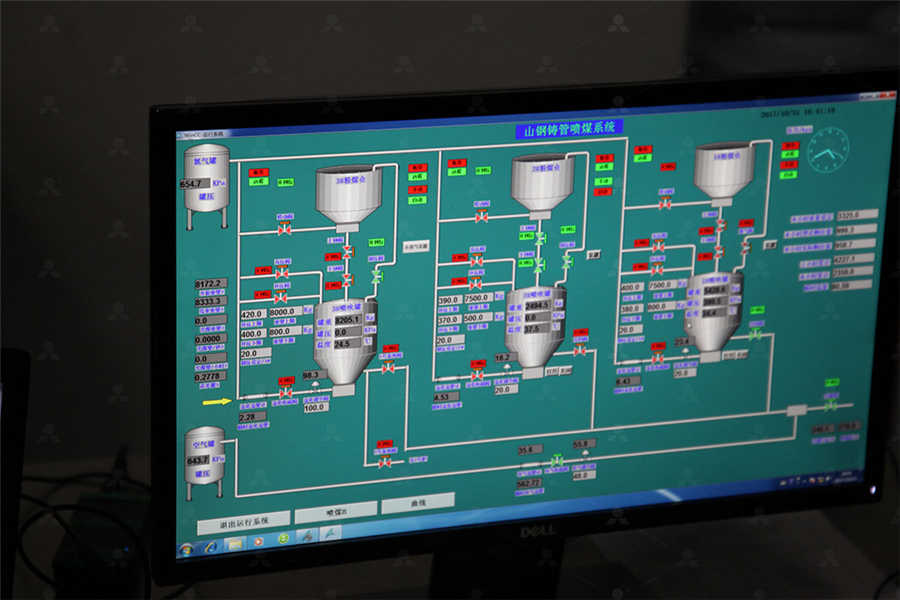

Webcomponent of the ATOX® mill, FRMTM mill and OK™ mill for many years A range of rotary sluice sizes and capacities are available to match different needs Many applications The rotary sluice can be used in many applications where lumpy materials are fed into process machinery It is most commonly used for vertical rollerWebContinuous ATOX® mill health monitoring and incident support; regular reports summarising alarms and recommendations; clear, actionable insights that you can implement to reduce operating costs and optimise performance Outcome: This means you can predict potential problems in critical components or subsystems in the mill circuit and Online condition monitoring services for ATOX® mills

ATOX mill split oil seal

WebATOXmill availability The new split seal can be replaced inside the mill, without removing the grinding rollers New ATOX 275 mills and bigger are today as standard equipped with the split seal arrangement For previously supplied ATOX mills the split seal design has also been introduced Conversion kits are now available forWebMay 10, 2022 44K views, 184 likes, 5 loves, 11 comments, 98 shares, Facebook Watch Videos from World Cement Engineers: How to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill #engineeringHow to Work FLsmidth OK Mill # #flsmi #okmill #atox #atoxmill

ATOX® Coal Mill G7 Equipment

WebRollers help handle virtually any type of coal The ATOX® Coal Mill’s large rollers can handle up to 200mm feed lumps, reducing the need for a separate crusher Large rollers also help ensure a thick grinding bed for maximum uptime The roller segments are reversible which ensures the highly durable materials are fully utilisedWebFeb 5, 2013 This video is about Atox Mills Hydraulic Unit for grinding rollers Process carried out through various control valves mounted on a hydraulic block called BlAtox Mill Hydraulic unit animation YouTube

Atoxmill G7 Equipment

WebAtoxmill; OK™ Pro+ Ceramic Wear Segments; HiChrome Wear Segments; SAG Mill; Press filters; Vertical shaft impact crusher (VSI) FJ JAWS; CONE CRUSHERS; KREBS® slurryMAX ™ XD; KREBS® millMAX™ slurry pumps; KREBS® UMD™ Ultimate Mill Discharge Slurry Pump; vMAX™ vertical slurry pumps; KREBS® Technequip® TG Knife WebApr 26, 2023 Cement Manufacturing Presentation PPT Cement Plant Chemistry Manufacturing Process Raw Mix Design, Burnability Cement Quality ATOX Mill Kiln Alignment Analysis Kiln Ovality Analysis Kiln Roller Adjustment and Skew Kiln Tire and Roller Reconditioning Phillips Kiln Services Introduction 6 January 2023Training, Seminar Technology For Engineers To become a Part

Vsi Crusher Coal Mill Structure ATOX – KM 275

Webcrushing ore using atox mill « coal crusher working principle of atox raw mill gulin crusher km 275 crusher structure of atox mill stone crusher concrete crushing work breakdown structure – Grinding Mill ChinaWebMay 23, 2013 atox mill – Scribd commenced the There is a number of arrangements for raw material grinding systems involving vertical roller mills 20 ATOX Raw Mill 1 2 3 Mill flsmidth atox vertical mill Mining Quarry Plant

Atox Raw Mill PDF Mill (Grinding) Bearing (Mechanical) Scribd

WebThe ATOX mill is easily adapted to this situation, as it comes with an oversize nozzle ring and an oversize separator Basic design concept The grinding table of the ATOX raw mill has a flat, horizontal grinding track encircled by an adjustable dam ring and an adjustable nozzle ring equipped with an air guide cone The dam ring is made up of WebThe ATOX mill will particles up to the separator that lets the grind and dry coal containing more than 20 final product proceed to the mill outlet per cent moisture in one operation while returning the coarse fraction to the table for further grinding Working principles The ATOX Coal Mill PDF Mill (Grinding) Bearing (Mechanical)

Bradley White on LinkedIn: #vrm #coalmill #atox #atoxmill

WebHardfacing a coal mill at a large cement works in Wales, January 2021 #vrm #coalmill #atox #atoxmill #hardfacing #cladding #rebuild #repair #hardfacingWebFind Clamping Sets Kits at MSC Industrial Supply, serving the metalworking, safety, and MRO industries for over 75 yearsClamping Sets Kits Clamps Clamping Components MSC Industrial Direct